A fully integrated field service management platform that empowers organisations to transform each stage of service delivery and experience unprecedented results.

WELCOME TO TOTALMOBILE

We’re passionate about making work and the lives of mobile workers better, with our unparalleled Field Service Management Software

OUR SECTORS

Breaking Boundaries Across Multiple Industries

Totalmobile’s suite of products are delivering benefits across a wide range of sectors. Learn how we can help your organization transform how services are delivered.

OUR Full Product Suite

Innovative Capabilities That Transform Field Service Management

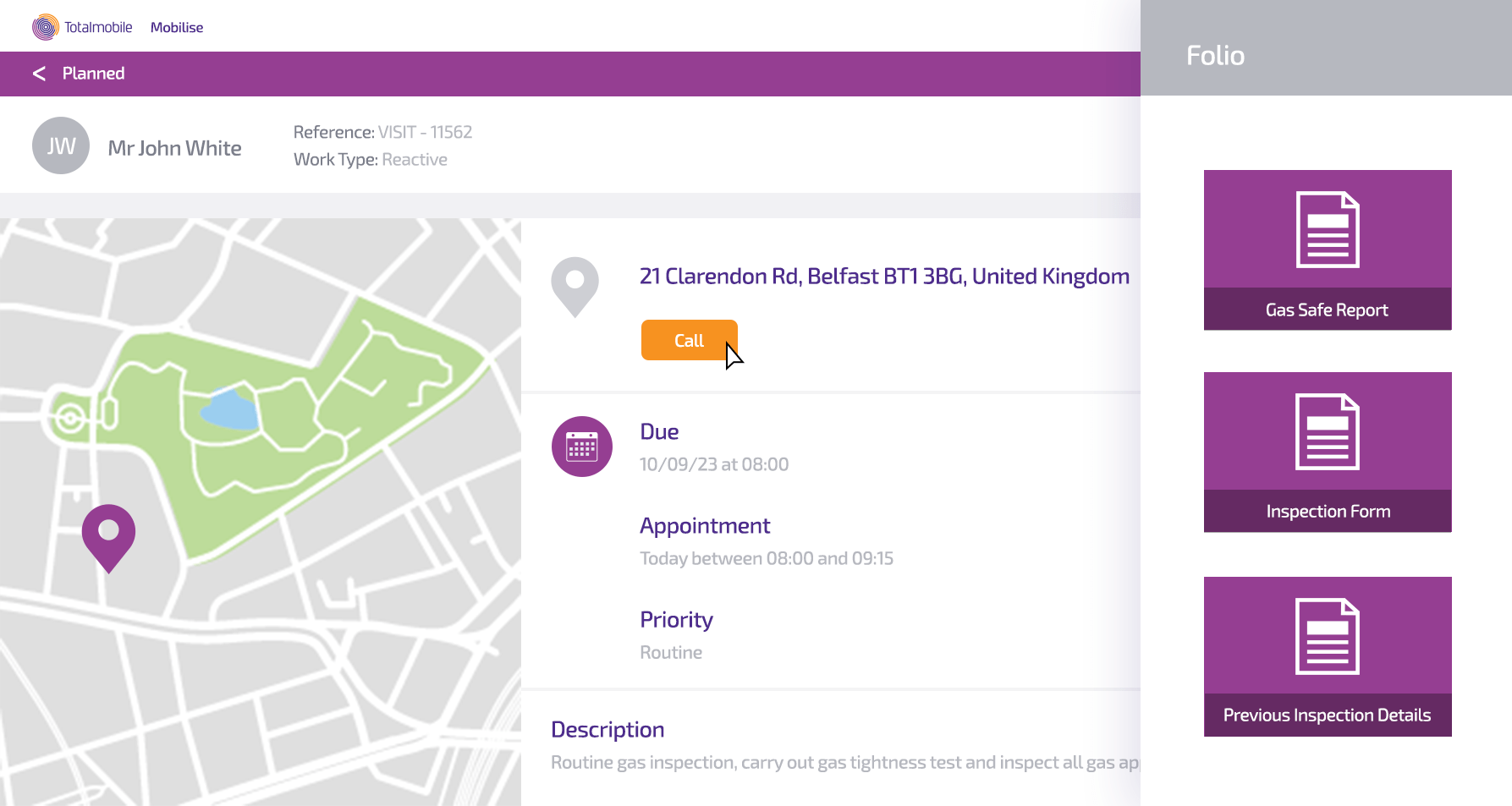

Mobilise

Mobile Working

Mobile workforce management solution that empowers the mobile workforce with the ability to capture intelligent data and access the information they need at the point of service

POPULAR FEATURES

Data Capture

Record all relevant job information, including photos and client signatures, via a mobile device at the point of service delivery.

Workflow Management

Guide staff through a series of pre approved workflows and status updates to ensure services are delivered in a compliant and consistent manner.

Folio Access

Provide staff with the ability to access all relevant job related information, providing them with the background details they require to deliver a great service.

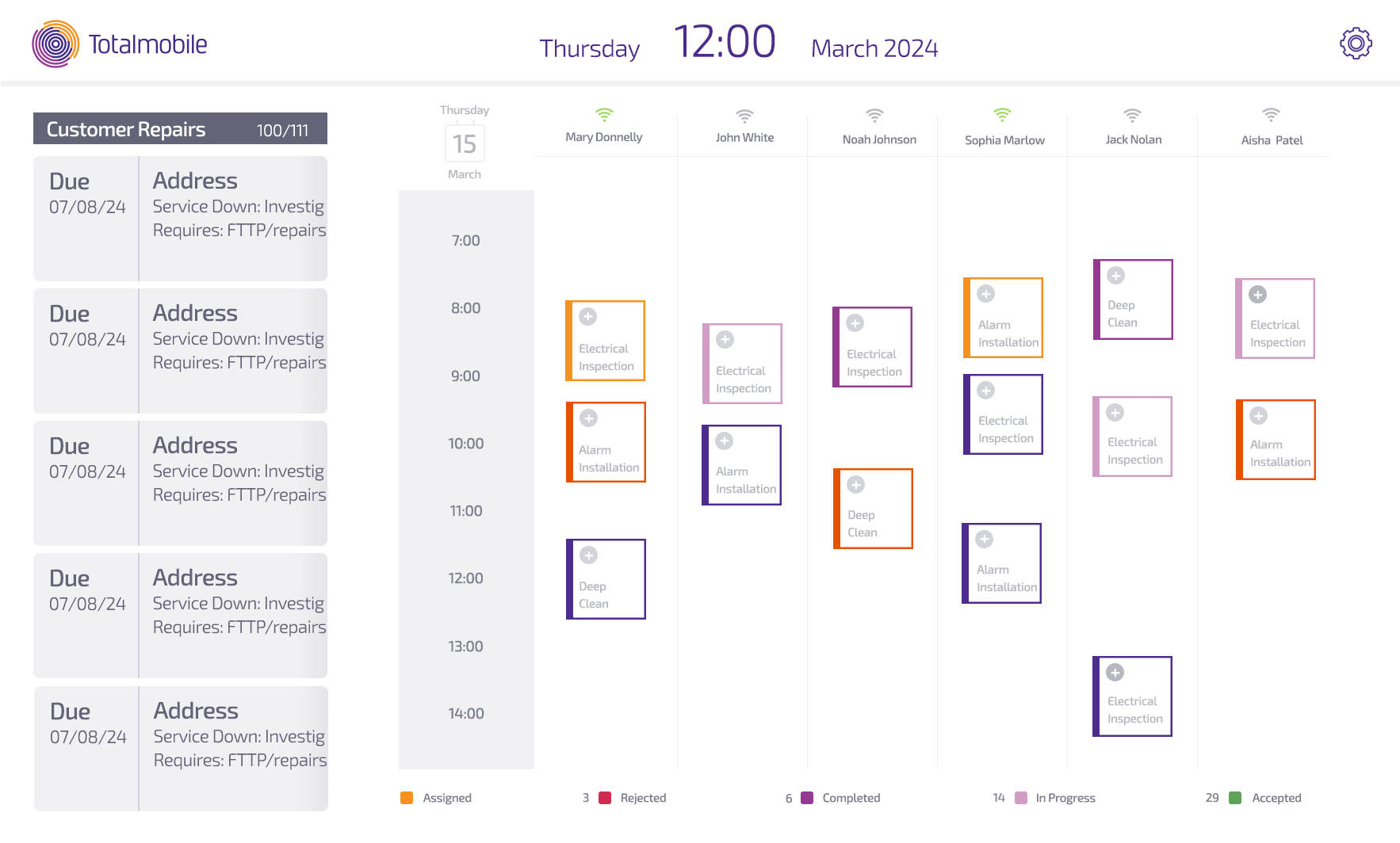

Optimise

Workforce Scheduling

Workforce scheduling technologies that ensures the efficient allocation of resource to achieve complex scheduling goals, based on time, location, availability and service levels.

POPULAR FEATURES

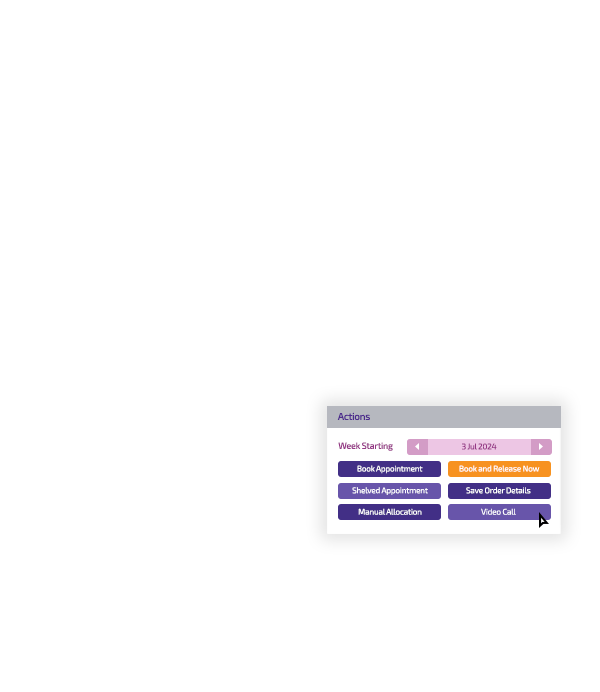

Manual Advance Scheduling

Empower planners to view all required visits and efficiently schedule planned work to available resources.

Automated Advance Scheduling

Take advantage of advanced scheduling algorithms that dynamically create the most effective schedule based on an individual organisation’s scheduling objectives.

Dynamic Dispatch

Assign work to staff one job at a time, based on skills location and work requirements, after they have completed their most recent visit.

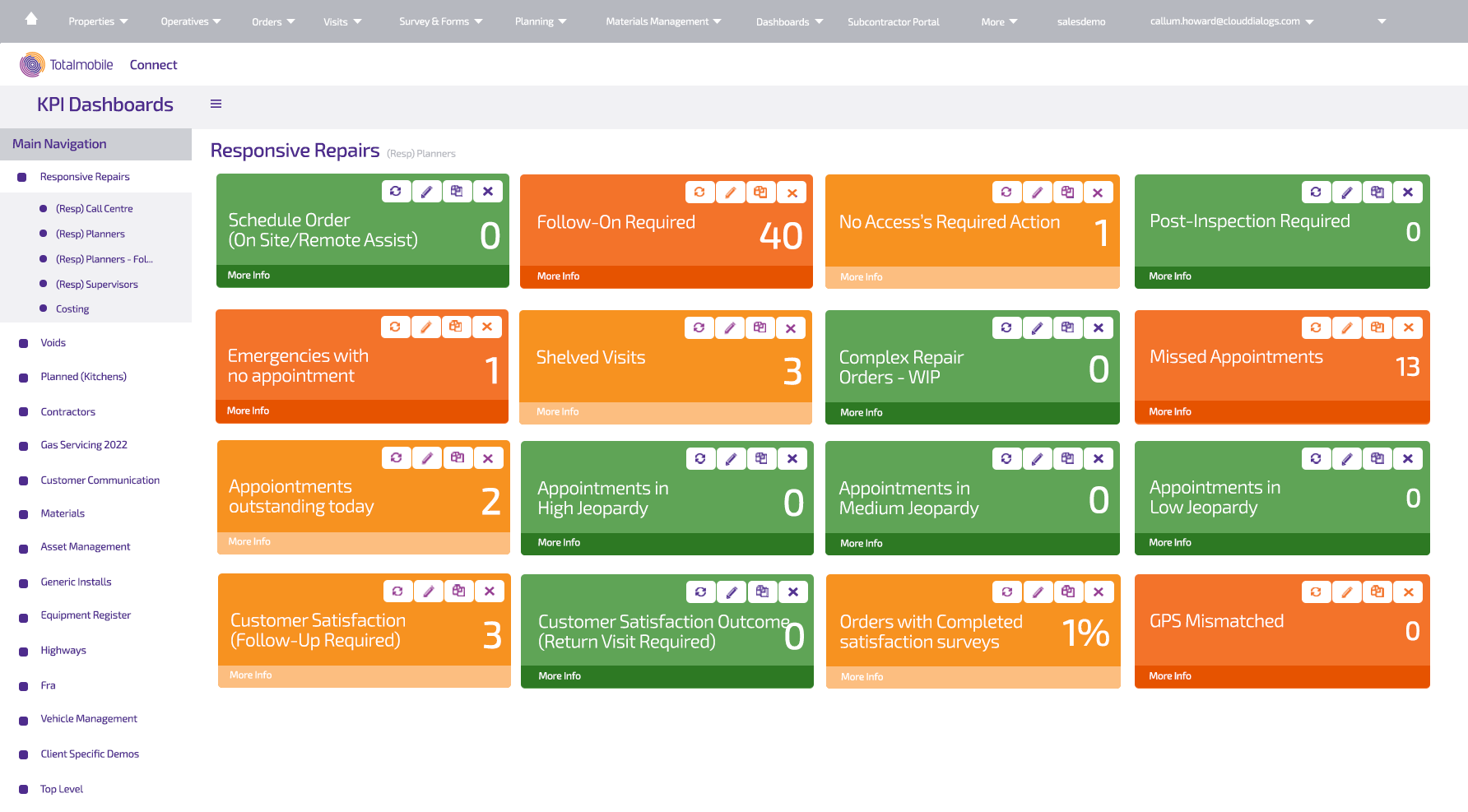

Connect

Work Order Management

Intuitive job management solution that provides the visibility and control over complex tasks, enabling the streamlined delivery of work and the ability to react to potential risks.

POPULAR FEATURES

Self Contained WOM

A fully integrated, cloud based job management system that provides visibility and control over all work orders.

Stock Management

Track regularity of stock usage, streamline the ordering process and keep a close eye on material costs.

Remote Assistance

A real time video based support capability that enables an operative at base to provide support to a field worker or service user.

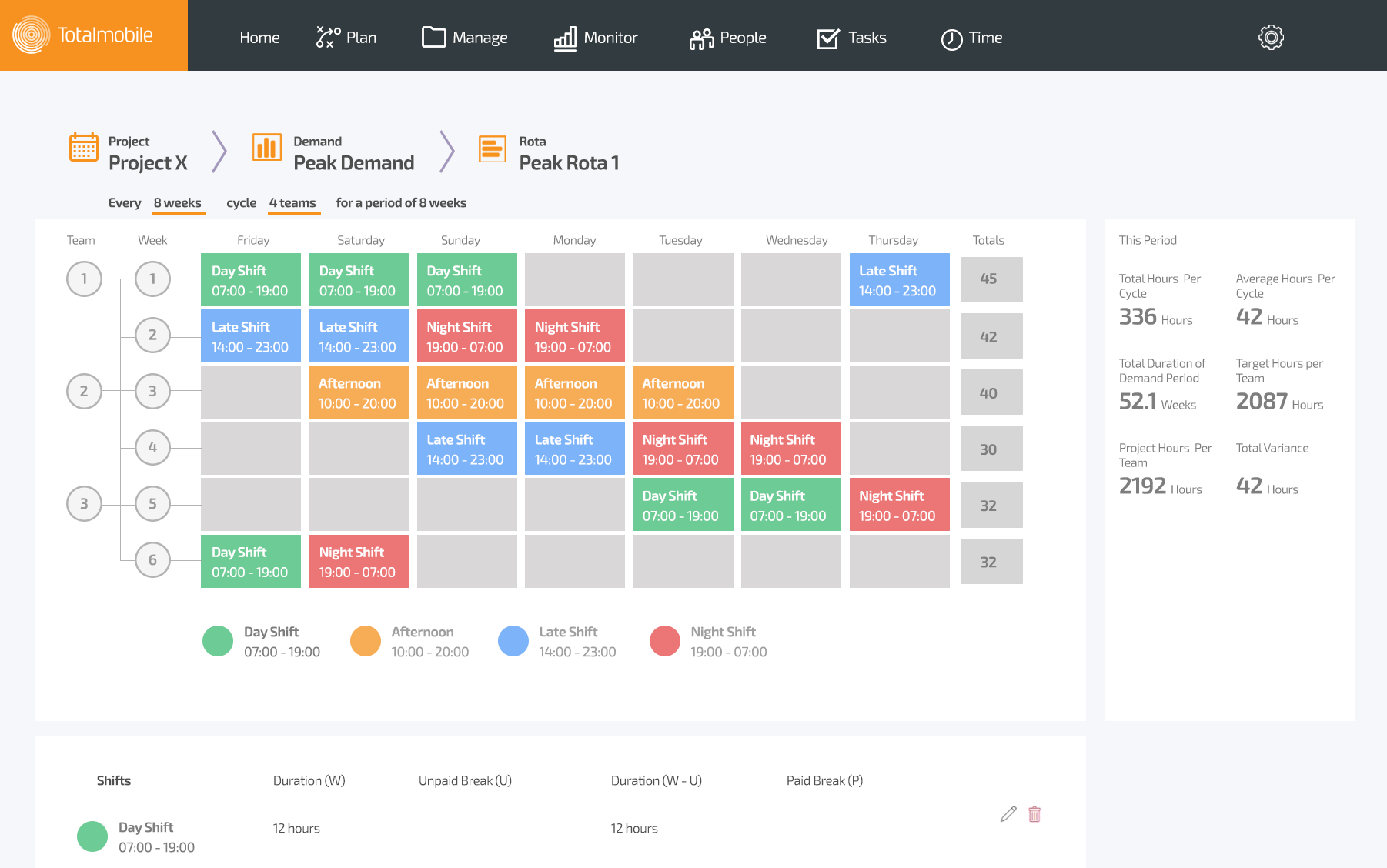

Organise

Rostering Solution

Flexible, comprehensive solution that enables organisations to deal with complex rostering challenges and ensure the right people, with the right skills are available at the right time.

POPULAR FEATURES

Automated Roster Allocation

Creates efficient rosters that meet all KPIs and compliance standards, based on staff availability and service demand

Staff Self Service Portal

Provides visibility of rosters and assigned shifts, while enabling staff to highlight availability and record absences.

3rd Party Brokerage

Integrate with contingency staff suppliers to efficiently fill any rostering gaps.

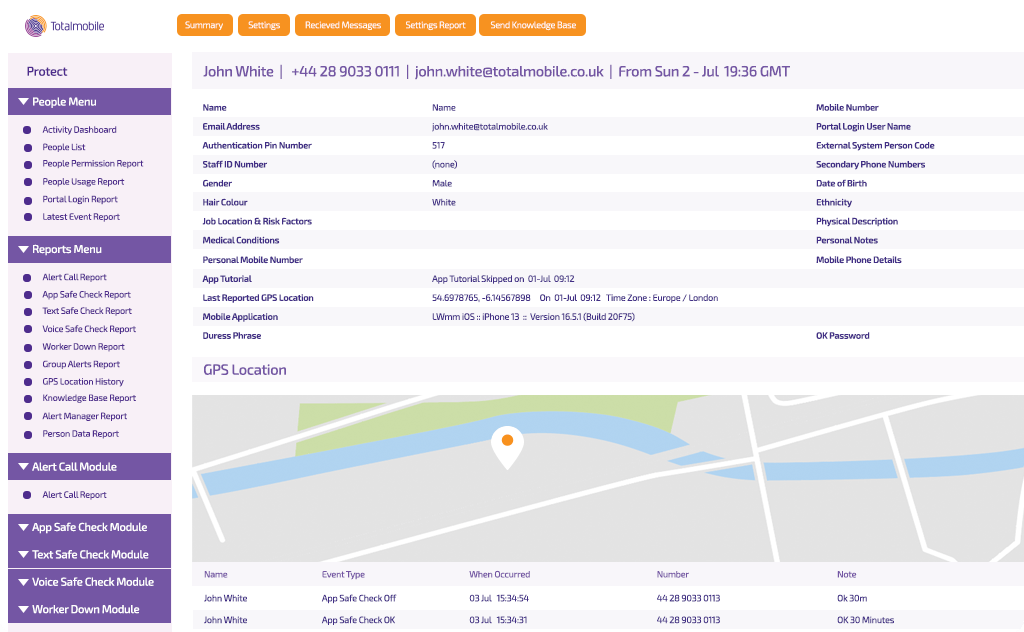

Protect

Lone Worker Protection

Alert and location-based technologies that enables organisations to ensure the safety employees and rapidly react to risks in the field

POPULAR FEATURES

Alerts

Receive a range of different alerts from who can then be connected with a response centre to escalate the situation as necessary.

GPS Tracking

Easily view the location of all field workers so they can be located in an emergency situation.

Managed Service

A fully managed service that offers a low cost of ownership and presents all key lone worker safety data via real time reports.

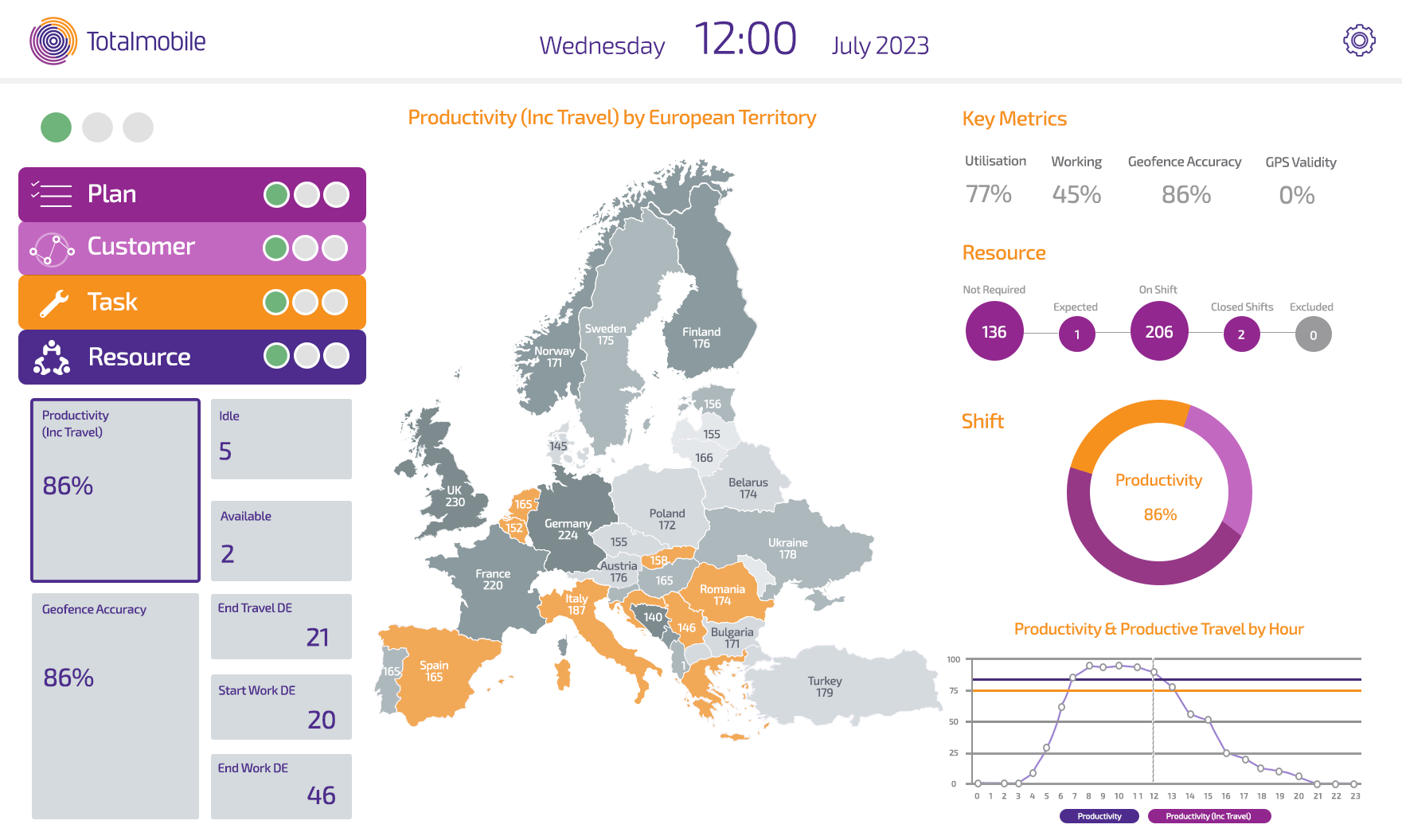

Insight

Access Analytics

Complete operational intelligence that offers an unprecedented overview of operational performance, as it unfolds.

POPULAR FEATURES

Historic Operations Analysis

Assess a comprehensive range of reports that provide an overview of past operational and employee performance.

Real-time Operational Analysis

Managers are provided with a live view of all aspects of ongoing service delivery with potential risks clearly identified.

Virtual Coach

Embraces historical data and machine learning to provide guidance on actions to improve future service delivery.

Blogs, News & Updates

See Our Demo for a Deeper Insight Into Our Field Service Management Software

See How Totalmobile Helps your Organisation deliver More Services of the Highest Quality at Reduced Cost.